Abstract

Background. The bond stability between polyetheretherketone (PEEK) materials and composites is a novel concern, and evidence regarding bond strength is limited. To date, no study has comprehensively evaluated the effect of different surface treatments, adhesive agents and composite materials on the shear bond strength (SBS) of various PEEK materials.

Objectives. The aim of the study was to compare the SBS between 2 PEEK materials and different indirect composites applied after the application of various surface pre-treatment methods and adhesives.

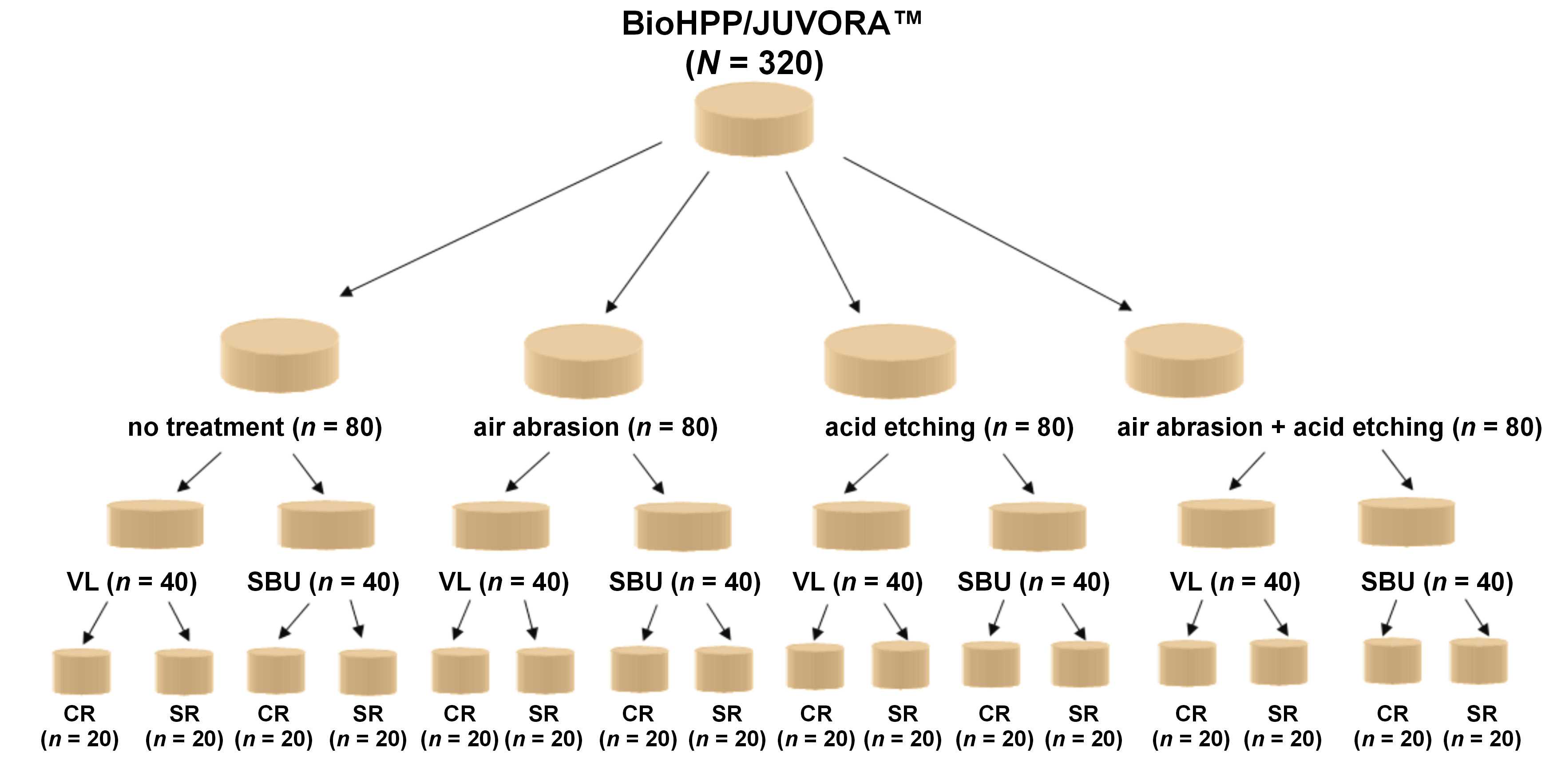

Material and methods. A total of 328 PEEK specimens (JUVORA™ (unfilled PEEK material, n = 164); BioHPP (compound containing 20% nanoceramic-filled PEEK, n = 164)) were divided into 4 groups according to the applied surface treatment: no treatment; air abrasion; acid etching; and acid etching + air abrasion. Subsequently, all specimens were conditioned with visio.link (VL) or Single Bond Universal (SBU). The specimens were veneered with crea.lign composite (CR) or SR Nexco composite (SR), and the bond strength values were measured. The co-variance analysis of variance (ANOVA) was performed to analyze the data (α = 0.003).

Results. The SBS values for BioHPP specimens were significantly higher than the values for JUVORA™ specimens in the no treatment group (p < 0.001). The highest SBS values were detected between BioHPP and SR (22.54 ±1.22 MPa), and between JUVORA™ and SR (21.45 ±1.43 MPa) after acid etching and conditioning with VL (p < 0.001). The surface treatments, composites and adhesives affected the SBS between the composites and PEEK materials.

Conclusions. Following air abrasion or acid etching of surfaces, conditioning with VL and aesthetic veneering with SR may be a more reliable clinical application than other surface treatments and adhesive–composite combinations for PEEK.

Keywords: shear bond strength, polyetheretherketone, surface roughness, indirect composite, piranha acid

Introduction

Dental materials that closely resemble tooth color have replaced metallic alloys due to increasing aesthetic expectations of the patients.1 Therefore, clinicians prefer materials that closely match the color of natural teeth.

Polyetheretherketone (PEEK) is a high-performance polymer of the polyaryletherketone family.2 Recently, PEEK used in orthopedics has also become popular in the field of dentistry due to its good malleability and bone-like elasticity.3, 4, 5 Polyetheretherketone is a semi-crystalline, polyaromatic, synthetic, and polymeric material widely used as a biomaterial for custom implant abutments, frameworks of removable partial dentures, and fixed partial dentures.6 In addition, PEEK possesses outstanding properties such as heat resistance, chemical stability, biological inertness, good biocompatibility, solvent properties, durability, excellent electrical insulation, toughness, and a better esthetic appearance than conventional metal frameworks.7, 8 Because of its low density (1.32 g/cm3) and low elastic modulus (3–4 GPa), the use of PEEK has been preferred in the field of dentistry.9, 10 Moreover, PEEK is reinforced with either carbon or glass fibers of varying lengths, spherical ceramic filler microparticles, barium phosphate (BaSO4), or titanium dioxide (TiO2) with filler contents up to 30%.11, 12, 13, 14 BioHPP, a compound containing 20% nanoceramic-filled PEEK and 20% ceramic fillers, is a high-performance polymer with high biocompatibility, excellent mechanical properties, high temperature resistance, and chemical stability.15, 16, 17, 18 However, the clinical use of PEEK as a monolithic restoration is limited due to its low translucency and snow-white color.19 Therefore, the material is veneered with composite resin to achieve acceptable aesthetic outcomes.20 Yet, there are problems in the direct bonding of the material to composite veneer materials.21 The inertness of PEEK makes it difficult to bond with composite veneer without the implementation of surface treatments and adhesive materials.3 Earlier studies have examined the effect of various surface treatments on the bond strength of PEEK to composite materials.22, 23

There are 2 main methods of surface treatment with PEEK: mechanical and chemical.23, 24 Air abrasion, bur grinding, laser, and plasma spray applications are mechanical treatments,25, 26 while the application of strong etching solutions is a chemical treatment.21 Additional etching of PEEK with sulfuric acid or piranha solution (sulfuric acid + hydrogen peroxide) has been shown to significantly increase the initial bond strength of the polymer.21, 27 In a previous study, the effect of acid etching treatment following air abrasion was compared to air abrasion, acid etching, and control groups.14 The highest bond strength values were reported for the group that underwent acid etching without mechanical treatment.14 However, the effect of combined surface treatments on different PEEK materials has not been evaluated.

In addition, the use of solvents containing methyl methacrylate (MMA) or phosphate monomer, and low viscosity of adhesives, can contribute to the adhesion of resin–matrix composites.28, 29 Previous studies have reported that adhesive systems containing MMA are capable of establishing a sufficient bond to PEEK.30, 31 Moreover, the shear bond strength (SBS) depends on the properties of the composite veneer material.32, 33 In a previous study, the bonding ability of acid-etched PEEK surfaces to the light-curing microparticle composite (VITA VM LC) and the Sinfony composite materials without adhesive conditioning was evaluated.20 The higher bonding values were obtained when Sinfony composite was used.20 This phenomenon was attributed to the enhanced penetration into micropores that results from acid etching due to the low viscosity of Sinfony composite in comparison to VITA VM LC.2, 19 In addition, the composition of VITA VM LC can be responsible for the observed differences between composites, given the established role of bisphenol A-diglycidyl methacrylate (Bis-GMA) as a viscous polymer.34

The shear bond strength values between PEEK and composite veneer must be at least 10–12 N to be considered clinically acceptable.35 However, the extent of knowledge concerning the potential and limitations of each treatment, with its particular specific effects, is limited, and there is a lack of clinically accepted standard protocols for enhancing PEEK frameworks to composite veneer materials.21 There is no consensus regarding the surface treatments, adhesive agents and composites applied in PEEK materials. Therefore, the bonding properties of PEEK materials should be examined further.

The purpose of the study was to compare and evaluate the effect of surface treatments, adhesive agents and composite veneer materials on the SBS of various PEEK materials to different composite materials. The first null hypothesis was that the use of adhesive agents and composite veneer materials would not affect the SBS of the PEEK materials. The second null hypothesis posited that there would be no differences between the SBS values of both PEEK materials.

Material and methods

In the present study, 2 different types of PEEK materials were examined: an unfilled PEEK (JUVORA™; JUVORA Ltd, Thornton Cleveleys, UK); and a compound containing 20% nanoceramic-filled PEEK (BioHPP; bredent medical GmbH & Co.KG, Senden, Germany). The characteristics of the materials used in the present study are displayed in Table 1. The sample size was calculated using the G*Power software, v. 3.0.1. The minimum number of specimens was determined to be 297, with an effect size (f) of 0.252, a power of 0.95 (1−β error probability), and a significance level of 0.05 (α error probability). Considering the results of the power analysis, a total of 328 specimens were prepared for the study.

Specimen preparation

Rectangular blocks of both types of PEEK were obtained from prefabricated PEEK discs using computer-aided design/computer-aided manufacturing (CAD/CAM). The blocks were cut with a slow-speed precision saw (IsoMet 1000 Precision Cutter; Buehler, Lake Bluff, USA). A total of 328 rectangular specimens measuring 7 mm × 7 mm × 4 mm were prepared, with 164 allocated for each type of PEEK. All specimens were embedded in acrylic resin (SCANDIQUICK; SCAN-DIA GmbH, Hagen, Germany), with a diameter of 22 mm and a height of 18 mm. The specimens’ surfaces were polished underwater for 10 s using an automatic polishing device (EcoMet®/AutoMet® 250; Buehler) and silicon carbide (SiC) abrasive papers of varying grit levels (600, 800 and 1,200). Subsequently, the specimens were cleaned for 10 min using an ultrasonic machine (Transsonic T700; Elma, Singen, Germany), and the surfaces of the specimens were dried using an air pressure process.

Application of surface treatments

Both BioHPP and JUVORA™ PEEK specimens were further divided into 4 subgroups according to the surface treatment method (n = 41 specimens/group). The first group was a control group, to which no surface treatment was applied. The second group was the acid etching group. In this group, piranha solution (a mixture of 98% sulfuric acid and 30% hydrogen peroxide in a ratio of 10:3) was applied to the surfaces of the specimens using a micropipette for 30 s, followed by a rinse with distilled water for an additional 30 s. The third group was the air abrasion group, in which the surfaces of the specimens were sandblasted (Basic Classic; Renfert Richardson, Richardson, USA) with 110-mm aluminum oxide particles (Cobra; Renfert, Hilzingen, Germany) at a pressure of 0.4 MPa, perpendicularly from a 10-mm distance for 10 s. In the fourth group, both of the abovementioned surface treatments were applied. Afterward, all specimens were cleaned with distilled water in an ultrasonic machine (Transsonic T700) for 10 min and air-dried. One specimen was selected from each of the 8 PEEK subgroups with different surface treatments for scanning electron microscopy (SEM). A total of 8 specimens were examined under a scanning electron microscope (S-4800; Hitachi, Ltd., Tokyo, Japan). After the respective surface treatment and sputter coating with gold alloy nanoparticles, an examination of a conductive layer of approx. 15 nm was conducted using a field emission SEM under ×1,000 magnification.

Surface topography measurements

The surface roughness (Ra) of 320 PEEK specimens was examined with a profilometer using a 90° detection device (Surtronic® S-series; Taylor Hobson, Leicester, UK). The diameter of the diamond probe tip was 2 μm. For each specimen, 5 measurements (3 vertically and 2 horizontally) were performed, with a measurement track of 6 mm. The distance between the tracks was 0.3 mm. The mean Ra of each sample was calculated.

Bonding procedure

The specimens of each of the 4 surface treatment PEEK groups were further subdivided into 2 different adhesive agent groups: VL (visio.link; bredent medical GmbH & Co.KG); and SBU (Single Bond Universal; 3M, Seefeld, Germany). Visio.link was applied to the surfaces of the PEEK specimens using a small brush and the adhesive composite furnace (Labolight DUO; GC, Leuven, Belgium), and polymerized lightly for 120 s. Single Bond Universal was applied to the surfaces of the PEEK specimens for 20 s, dried for 5 s and lightly polymerized (Elipar S10; 3M ESPE, Istanbul, Turkey) at a light intensity of 1,200 mW/cm2 for 10 s.

After adhesive conditioning procedures, a special cylindrical mold with an inner diameter of 2.3 mm and a height of 3.0 mm was used to apply the composite to the surfaces that had been conditioned with adhesives. The mold was positioned on the PEEK specimen surface, filled with the veneering composite and lightly cured (Elipar S10) at a light intensity of 1,200 mW/cm2 for 20 s. Subsequently, the composite veneers were polymerized using a composite furnace (Labolight DUO) for 5 min, following the standard program (190–220 mW/cm2 depending on the wavelength). Crea.lign dental composite (CR) (bredent medical GmbH & Co.KG) was applied to the surfaces of half of the specimens from each group, and the other half of the specimens were coated with SR Nexco composite (SR) (Ivoclar Vivadent AG, Schaan, Liechtenstein). Subsequently, all specimens were stored in distilled water at 37°C for 24 h. Figure 1 presents the overview of the study design.

Bond strength measurement and failure modes

The shear bond strength between composites and PEEK materials was measured using a testing machine (Shear Bond Tester; Bisco Inc., Schaumburg, USA). The specimens were positioned and fixed in the specimen holder, ensuring that the adhesive specimen surface was parallel to the loading piston. The load, characterized by a crosshead speed of 1 mm/min, was applied to the interface of the composites and PEEK specimens until failure occurred.

The SBS values were calculated using the following formula (Equation 1):

where:

F – fracture load [N];

A – bond area [mm2].

The debonded area was examined with a stereomicroscope (M3B; Wild Heerbrugg Ltd., Heerbrugg, Switzerland) at ×35 magnification for fracture analysis, and failure modes were recorded as adhesive, cohesive or mixed.

Statistical analysis

The normality of the data distribution was tested using the Shapiro–Wilk test. The Kruskall–Wallis and Mann–Whitney U tests were used to compare groups with non-normally distributed Ra values (Table 2). Furthermore, the analysis of covariance (ANCOVA) (Table 3) was performed with a normal distribution to state the effects of surface treatments, composite types and adhesive agents on the SBS values of PEEK materials to composite veneers among the groups. A comparison of the SBS values of PEEK materials was conducted using an independent samples t-test and the Holm–Bonferroni adjustment. In addition, Pearson χ2 and Fisher’s exact test were employed to determine the distribution of failure modes among the different treatment groups, with a statistical significance level set at p < 0.05.

Results

Surface roughness

In this study, BioHPP and JUVORA™ were compared. A statistically significant difference in the Ra values was observed between the surface treatment groups (p < 0.01) (Table 2). The values noted in the control group were lower than those in the other 3 groups for both PEEK materials (p < 0.01). The values obtained from the air abrasion and acid etching + air abrasion groups were lower than those from the acid etching group (p < 0.01). The surface roughness of BioHPP exceeded that of JUVORA™ for acid etching treatment (p < 0.01). Other pairwise comparisons revealed no statistically significant differences (p > 0.05).

Shear bond strength

The analysis of covariance revealed that the PEEK materials, surface treatments, adhesive agents, and composite materials had significant effects on the SBS values (p < 0.001) (Table 3). A significant two-factor interaction was observed between the PEEK materials and surface treatments (p < 0.001), as well as between the PEEK materials and adhesive agents (p < 0.001). There were borderline significant two-factor interactions between the PEEK materials and composites (p = 0.051). Furthermore, the three-factor interaction among the PEEK materials, adhesive agents and composites was significant (p = 0.003), as well as the correlation between the PEEK materials, surface treatments and bonding agents (p < 0.001). In addition, a significant interaction was noted among surface treatments, adhesive agents and composites (p = 0.005), as well as among the PEEK materials, surface treatments, adhesive agents, and composites (p < 0.001).

The differences between the SBS values based on the PEEK materials, composite materials and adhesives used are presented in Table 4. In the control group, the values for BioHPP specimens were significantly higher than the values for JUVORA™ specimens when the combination of the same composite material and the same adhesive was used (p < 0.001). In the air abrasion group, there were no significant differences between the SBS values of BioHPP and JUVORA™ specimens when VL adhesive and SR composite were used (p = 0.006). However, the SBS values of BioHPP were higher than those of JUVORA™ when using other adhesive and composite combinations (p < 0.001). When applying VL adhesive and SR composite, the values of BioHPP were not significantly different from the values of JUVORA™ after acid etching treatment (p = 0.083). Similarly, no significant differences were observed between PEEK materials when SBU and CR composite were applied to acid-etched surfaces (p = 0.360). For other combinations of bonding and composite materials in the acid etching group, the SBS values of BioHPP were significantly higher than the values of JUVORA™ (p < 0.001). In the acid etching + air abrasion group, the SBS values of BioHPP were significantly higher than the values of JUVORA™ when SBU and SR composite material were applied together (p < 0.001). The SBS values of BioHPP and JUVORA™ were not significant for the SBU and CR combination in the air abrasion + acid etching group (p = 0.069). However, the SBS values of JUVORA™ specimens were significantly higher than the values of BioHPP specimens for other adhesive and composite material combinations (p < 0.001).

Scanning electron microscopy

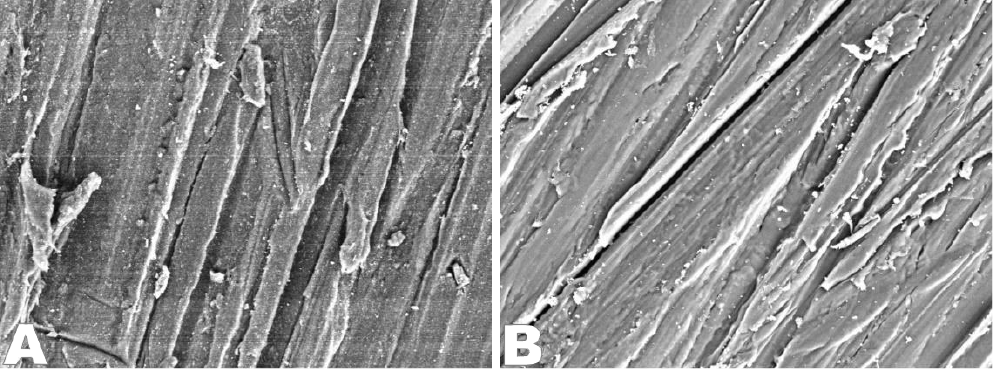

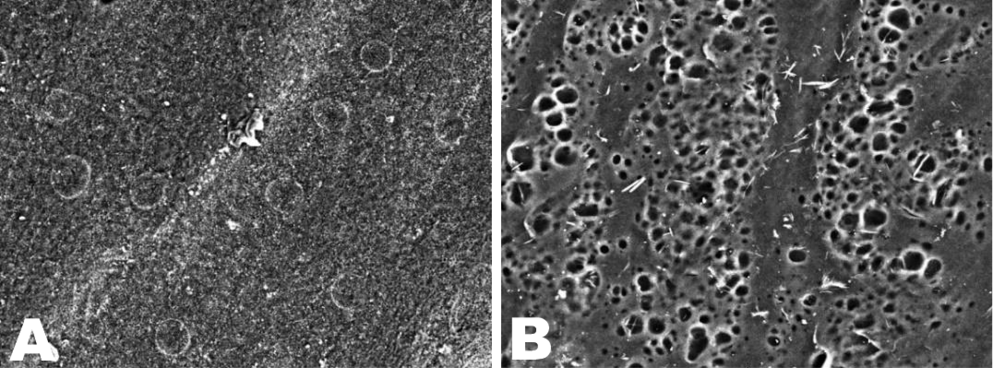

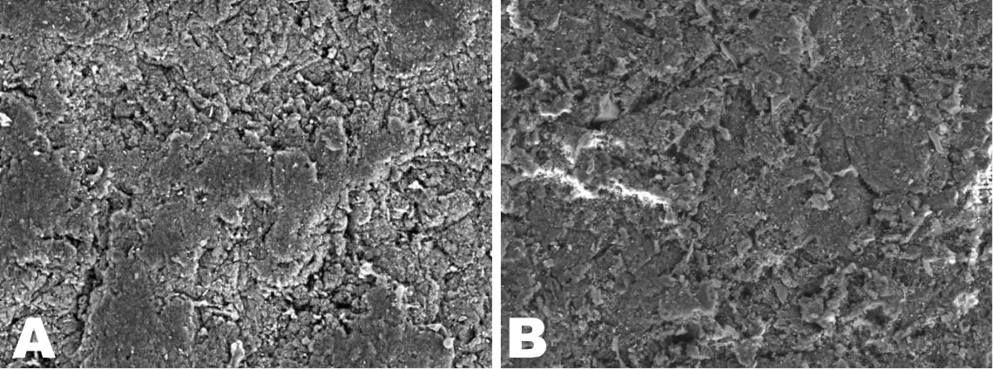

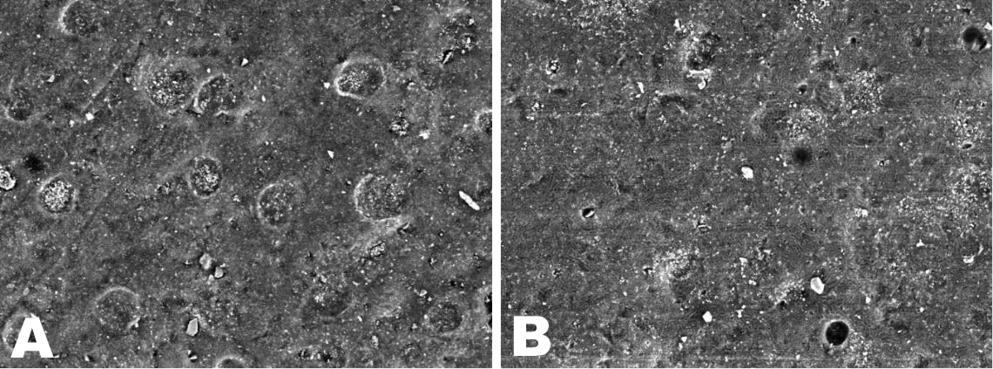

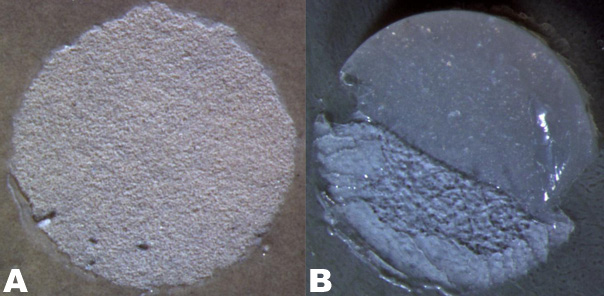

Following surface treatments, the SEM images of BioHPP and JUVORA™ were obtained (Figure 2, Figure 3, Figure 4, Figure 5). Irregular structures formed by abrasive papers were observed on the surfaces of the specimens even in the absence of surface treatment (Figure 2A,B). In the BioHPP specimens, the piranha acid-etched surfaces exhibited low porosity (Figure 3A), while the JUVORA™ specimens demonstrated a honeycomb pattern (Figure 3B). The regular structure underwent deterioration after air abrasion treatment, resulting in a formation of a recessed and protruding surface (Figure 4A,B). After air abrasion and piranha acid etching, the surfaces exhibited recessed and protruded features, in addition to the presence of porous areas (Figure 5A,B).

Failure modes

The failure types of PEEK materials are presented in Table 5. Adhesive and mixed failures were observed; however, no instances of cohesive failure were noted within the groups (Figure 6A,B). There were no significant differences between the failure modes of the materials for the control and acid etching + air abrasion groups (p > 0.05). In the air abrasion group, there were no differences in the incidence of adhesive failure between JUVORA™ and BioHPP for the SBU and CR combination (p = 0.178). However, adhesive failure was significantly more prevalent in JUVORA™ specimens in comparison to BioHPP for other adhesive and composite material combinations (p < 0.05). In the acid etching group, the incidence of adhesive failure was significantly higher in the JUVORA™ group compared to the BioHPP group for VL adhesive and SR composite (p = 0.019). However, no statistically significant differences were identified between the failure modes of PEEK materials when evaluated across other adhesive–composite material combinations (p > 0.05).

Discussion

The study demonstrated that surface treatment methods, adhesive agents and composite veneer materials had a significant effect on the SBS of both BioHPP and JUVORA™ to composites. Therefore, the first null hypothesis was rejected. Although there were no significant differences between the SBS values of BioHPP and JUVORA™ for some pairwise comparisons in the surface treatments groups, significant differences were observed between both control PEEK groups. Therefore, the second null hypothesis was partially rejected.

The SBS between the composite resin and the PEEK surfaces in the control group was significantly lower compared to the other surface-treated groups. Considering that the obtained SBS values were higher than the critical SBS value (10 MPa), it can be concluded that air abrasion, acid etching, as well as acid etching + air abrasion of both PEEK surfaces can be considered proper surface treatment methods for both BioHPP and JUVORA™.

Previous studies have examined the SBS of PEEK specimens following diverse surface treatments, including piranha acid etching and air abrasion.27 The authors have demonstrated higher bonding values with increased Ra as compared to untreated specimens.27 Elevated Ra values increase wettability by decreasing surface tension and increasing surface area.7 Airborne-particle abrasion results in improved microroughness of the substrate, whereas pre-treatment with acids increases the number of functional carbon–oxygen groups in the surface layer of PEEK.11, 12 Air abrasion with 100-µm aluminum oxide particles has been stated to improve SBS of PEEK to different composite resins.13 This finding is consistent with previous studies, which indicated that air-abraded PEEK surfaces exhibited lower SBS values between PEEK and composite veneer compared to etched PEEK surfaces.7, 28 The chemical surface treatment was more effective than the mechanical surface treatment. The present findings indicate that acid etching resulted in higher bond strength between PEEK material and composite veneer compared to the acid etching + air abrasion surface treatment method. Alumina particles attached to PEEK surfaces can reduce the mechanical interlocking between a composite veneer and PEEK. Additionally, the particles retained on the PEEK surfaces could hinder the formation of pores during acid etching treatment and reduce the flow of an adhesive agent into the pores of PEEK surfaces, subsequently decreasing SBS values.14 Furthermore, the SEM images of PEEK materials revealed more porous and permeable structures after acid etching (Figure 3A,B). In this study, higher Ra values (mean (M): 3.46 ±0.75 μm) were observed in the acid etching group specimens as compared with other groups. In addition, the values obtained in this study were congruent with the outcomes of previous studies that examined the bond strength of PEEK substrates.20, 25

On the other hand, it has been reported that the increase in Ra after surface treatment proved inadequate in establishing a reliable bond strength between PEEK and composite veneer materials.26 The enhancement of bond strength between PEEK and composite veneers requires conditioning with adhesive agents. Although there were no differences between the Ra values in this study, the difference between the SBS values indicates that chemical bonding exhibits greater durability than mechanical bonding. The composition of adhesive agents is a critical factor in determining bond strength between PEEK and composites.12 Previous studies have indicated that MMA-containing adhesive materials significantly contribute to the high bond strength.12 Therefore, the effect of an adhesive agent on SBS may be more pronounced than the effect of surface treatment methods.13 The chemical composition of adhesive systems plays a central role in the formation of chemical bonds between different polymers. To date, no studies have compared SBS across specimens with different bonding agents following a similar methodology, which makes it difficult to conduct a meta-analysis.21 In this study, the best bonding potential was observed in the VL-conditioned groups containing pentaerythritol triacrylate (PETIA), MMA monomers and additional dimethacrylates in solution. It can be assumed that PETIA dissolves the surface of PEEK, whereas MMA monomers cause swelling of the dissolved PEEK surfaces, and dimethacrylate monomers connect to the composite materials with 2 carboxyl groups as the bonding site. Although the use of SBU as the coupling agent in this study resulted in improved SBS values, the results were lower when compared to VL. This finding can be explained by the fact that a functional group of the bifunctional 10-methacryloyloxydecyl dihydrogen phosphate (10-MDP) monomer is occupied by a phosphate group, which in incapable to react chemically with the PEEK substrate or veneering resin composite.25 An exception to this phenomenon was observed in the BioHPP groups veneered with SR, wherein SBU showed a higher bond strength in comparison to groups conditioned with VL after acid etching + air abrasion treatment (p < 0.01). The molecular alterations of surfaces after a combination of mechanical and chemical treatment may be the underlying cause of the improvements observed in the chemical bond of 10-MDP monomer to the modified PEEK surface. Moreover, the presence of silane in SBU may facilitate the formation of bonds with the ceramic filler of BioHPP exposed after surface modification and contribute to the increased bond strength of the material.3 Similarly, polyalkenoic acid copolymer content of SBU can improve the bond strength between PEEK and composite materials.24

In the present study, the SBS values ranged from 16.28 MPa to 21.58 MPa when VL was used following air abrasion treatment, which aligns with the results of previous studies.23, 25 One of these studies compared the bond strength of the veneering resin composites to PEEK after the application of different adhesives and diverse pre-treatment specimens.25 The use of VL (18.0–28.8 MPa) resulted in higher SBS when compared to Clearfil™ Ceramic Primer (2.2–9.3 MPa) that contains 10-MDP. However, the waiting time between the application of surface treatments, adhesive agents and composite veneers was not mentioned in previous studies,23, 25, 31 which may be the reason for the different SBS values reported.

In this study, 2 composite veneers were used. In general, an increase in viscosity resulting from elevated filler content of dental composites may negatively affect mechanical retention.33 Because of its low filler content (19.8%) and low molecular weight (470 g/mol) of urethane dimethacrylate (UDMA) content, SR is a low-viscosity composite.35 Given that CR contains 50% ceramic particles, Bis-GMA, which possesses a higher molecular weight (512 g/mol), exhibits increased viscosity. In this study, specimens on which SR was applied demonstrated higher SBS values compared to CR, with the exception of 1 group. This phenomenon can be attributed to the enhanced mobility of SR into microroughness areas due to its low viscosity, which fosters good microretention. This finding is in agreement with the outcomes of the study conducted by Bötel et al.2 Similarly, another study compared 2 different indirect resin composites, Sinfony and GC Gradia, which were applied to PEEK specimens after undergoing different surface-roughening methods.19 The specimens veneered with low-viscosity Sinfony (50% filler rate) demonstrated higher bond strength values than the high-viscosity GC Gradia.19

In the present study, lower SBS values were found between JUVORA™ and SR resin for acid-etched surfaces in comparison with the corresponding values for acid-etched BioHPP surfaces. The observed difference may be caused by the presence of air voids in the acid-etched JUVORA™ surfaces, which may reduce the diffusion of monomers and composite material into the surfaces.28 However, this difference was not observed when CR composite was used in conjunction with SBU. This discrepancy may be attributed to the higher viscosity of CR compared to SR. Increased viscosity may equally preclude the penetration into the microretention areas of all PEEK surfaces.20 There were no significant differences between the SBS of BioHPP and JUVORA™ when air abrasion or acid etching surface treatment, VL adhesive agent, and SR composite veneer were applied. Therefore, both PEEK materials can be applied with the same protocol, resulting in comparable bond strength.

When examining the bond strength, it is necessary to evaluate the SBS test results and analyze the fracture mode in the bonding interface. It has been claimed that cohesive and mixed failures are correlated with higher bond strength values than adhesive failures.35 However, cohesive failures were not observed in this study, which is in agreement with another study on PEEK-indirect composite.12 Although there were no significant differences between the SBS results of BioHPP and JUVORA™ materials when VL–SR combination was used after air abrasion or acid etching, mixed fractures were found to be significantly higher in the BioHPP material. The reason for this difference may be exposed ceramic filler and increased microretention area of the BioHPP material.

Limitations

The results of this in vitro study have limited clinical validity, as oral conditions such as saliva, mastication forces and chemical agents from food and beverages were not incorporated. To ensure the validity of the results, further clinical studies are necessary.

Conclusions

In this in vitro study, significant effects of surface treatments, adhesive agents and composite veneer materials on SBS were confirmed for 2 PEEK materials. The SBS values between the PEEK and composite veneer materials were significantly increased after the administration of surface pre-treatment procedures and adhesive agents. There were significant differences between the SBS values of both PEEK materials and the control group. When air-abraded or piranha acid-etched PEEK surfaces were conditioned with VL, there were no significant differences between the SBS of the 2 PEEK materials to the SR composite. When piranha acid-etched surfaces or air-abraded + piranha acid-etched PEEK surfaces were conditioned with SBU, no significant differences were observed between the SBS of BioHPP and JUVORA™ materials to CR composite. In general, PEEK specimens conditioned with VL exhibited significantly higher bond strength in comparison to those conditioned with SBU.

Ethics approval and consent to participate

Not applicable.

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

Consent for publication

Not applicable.

Use of AI and AI-assisted technologies

Not applicable.